I'm only 2000 miles past my 1000 mile dealer service and my drive belt was a bit loose. Do not run with an under tensioned belt.

To check:

The bike should be on the ground with weight on wheels but no rider or other loads (on the jiffy stand is OK).

There is a little window in the belt guard below the swing arm ahead of the left saddlebag.

Push up with 10 pounds force using tension gauge HD-35381-A, so you see the gauge moving in the window.

With 12 inch shocks the belt deflection should be 1/4 - 7/16 inch as the load is applied.

With 13 inch shocks the belt deflection should be 3/8 - 9/16 inch as the load is applied.

To adjust tension:

Remove the E-clip on the right end of the rear axle, loosen the axle nut (36mm). Leave a little clamp pressure to keep things straight. Turn the left side axle hex head to rotate the tensioning cams (both sides will turn). Check tension. Torque the axle nut to 100 ft-lbs. Double check that the cams touch the swing arm bosses and the tension is correct. Replace E-clip.

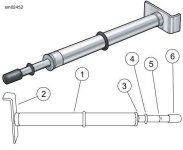

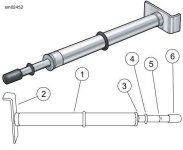

Tension gauge illustration:

To check:

The bike should be on the ground with weight on wheels but no rider or other loads (on the jiffy stand is OK).

There is a little window in the belt guard below the swing arm ahead of the left saddlebag.

Push up with 10 pounds force using tension gauge HD-35381-A, so you see the gauge moving in the window.

With 12 inch shocks the belt deflection should be 1/4 - 7/16 inch as the load is applied.

With 13 inch shocks the belt deflection should be 3/8 - 9/16 inch as the load is applied.

To adjust tension:

Remove the E-clip on the right end of the rear axle, loosen the axle nut (36mm). Leave a little clamp pressure to keep things straight. Turn the left side axle hex head to rotate the tensioning cams (both sides will turn). Check tension. Torque the axle nut to 100 ft-lbs. Double check that the cams touch the swing arm bosses and the tension is correct. Replace E-clip.

Tension gauge illustration: