Our bikes use an Engine Control Module (ECM) that controls Air/Fuel ratio (AFR) with feedback from Oxygen (O2) sensors in the exhaust. The ECM fuels the bike as commanded by a table of Lambda values. Lambda = AFR/AFRstoich. The stoichiometric air/fuel ratio is the chemically correct ratio of air to fuel for complete combustion to take place (about 14.7 for ordinary gasoline). The ECM uses lambda control so that it will still fuel properly with different blends of gasoline and those mixed with alcohol.

A value of one in the lambda table is stoichiometric. A value of .95 would be 5% rich, a value of .90 would be 10% rich. The stock narrow band sensors only function at about .975 or greater. The rest of the time the engine must operate open loop (no O2 sensor feedback is used).

The proper Lambda value is selected based on engine load and rpm. Richer settings are used at higher rpm and high engine load. Leaner at low power for emissions and fuel economy. Engine load is approximately proportional to Manifold Absolute Pressure (MAP). It is measured by a sensor in the intake manifold.

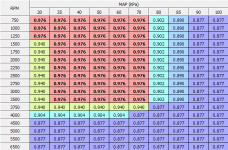

Here is the H-D Lambda table plotted in three dimensions (3D) for my 120ST engine:

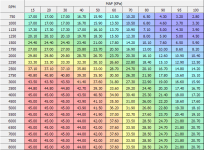

You can see the engine is kept lean most of the time and then switches rapidly to open loop at the high speed and load points. This can be made a little better with a performance tuner. Here is the 120R (race) engine Lambda table:

A little better but not much. This is a limitation of narrow band O2 engine control. High-tech lean burn water cooled engines have no problem with this, but it is not the best fueling for a hot running, high power, air cooled, high compression, good old fashioned Harley Twin Cam (used off road of course).

How to do better? Switch to wideband O2 control with "Target-Tune" from Dynojet Powervision. This system uses the factory Delphi ECM with all of its advanced features and mates it with wideband O2 sensors for Lambda feedback over the entire engine operating envelope. Now a fuel map can be designed that provides a smooth transition across all engine operating points along with the speed-density control provided by the Delphi ECM.

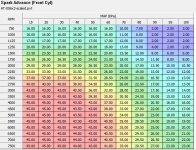

Here is the fuel table I developed and am running now in my 120ST engine. This was easy to build in WinPV software that works with a Power Vision tuner. The engine now runs as smooth as this table looks. I am super happy with it:

Converting to AFR for gasoline the top of the chart is 14.3 and the bottom is 12.8 AFR.

A value of one in the lambda table is stoichiometric. A value of .95 would be 5% rich, a value of .90 would be 10% rich. The stock narrow band sensors only function at about .975 or greater. The rest of the time the engine must operate open loop (no O2 sensor feedback is used).

The proper Lambda value is selected based on engine load and rpm. Richer settings are used at higher rpm and high engine load. Leaner at low power for emissions and fuel economy. Engine load is approximately proportional to Manifold Absolute Pressure (MAP). It is measured by a sensor in the intake manifold.

Here is the H-D Lambda table plotted in three dimensions (3D) for my 120ST engine:

You can see the engine is kept lean most of the time and then switches rapidly to open loop at the high speed and load points. This can be made a little better with a performance tuner. Here is the 120R (race) engine Lambda table:

A little better but not much. This is a limitation of narrow band O2 engine control. High-tech lean burn water cooled engines have no problem with this, but it is not the best fueling for a hot running, high power, air cooled, high compression, good old fashioned Harley Twin Cam (used off road of course).

How to do better? Switch to wideband O2 control with "Target-Tune" from Dynojet Powervision. This system uses the factory Delphi ECM with all of its advanced features and mates it with wideband O2 sensors for Lambda feedback over the entire engine operating envelope. Now a fuel map can be designed that provides a smooth transition across all engine operating points along with the speed-density control provided by the Delphi ECM.

Here is the fuel table I developed and am running now in my 120ST engine. This was easy to build in WinPV software that works with a Power Vision tuner. The engine now runs as smooth as this table looks. I am super happy with it:

Converting to AFR for gasoline the top of the chart is 14.3 and the bottom is 12.8 AFR.