I usually just wipe the cylinder with oil on and never had an issue . I also run a break in oil for the first 500mi. then change to Amsoil or Klotz. looks like a clearance or cylinder out of spec to me . make sure your shop is using a Hone plate when boring and honing your jugs. I also will heat cycle in the shop, run a couple miles let it cool check plugs, run it 25mi cool , 100mi cool, 500mi oil change and burn her down. some say give it 1000mi break in before you get into her but I hadn't had any issues on any builds yet .

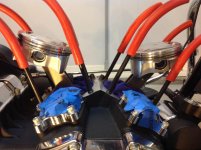

Yes, the machinist will bolt the cylinders to torque plates before performing his magic. What baffles me is how this was even an issue to begin with when cylinders were supposed to be bored to a specific size?