Since day one, my 120ST has been noisy on the top end and was very prominent when hot... especially between 2600-3000 rpms. I was told it was NORMAL and had dealt with it day by day.... I wasn't buying it. There is no way I should here top end noise at 80mph over an Arc XDI 600.4 amp pushing 4 high-end speakers.

I found out about ROCKOUTS on another forum a few months ago and decided then, that this could be a viable solution ( to correct a potential problem ) that I 'might' be having.

It never got better or worse... so I bought the $15 rockouts and hung them on the bench in the garage for a rainy/snowy day.

I picked up some adjustable pushrods and yesterday decided to tear into it... GLAD I DID!

Once I got in there ( following the manual ) and took the rocker support housing off the rear cylinder, it was obvious that 'something' just wasn't right.

First clue was the right side bolt on the exhaust side.. VERY HARD to get out compared to the other 3

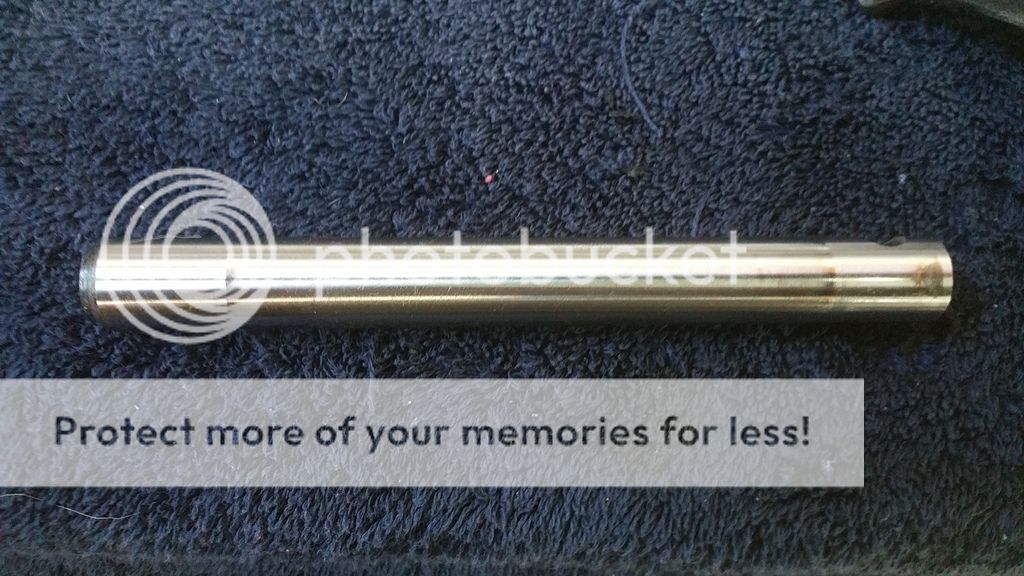

Second clue was the offset position of the rocker shaft itself...

Third clue was noticed looking into the bolt hole of the rocker support....

I found out about ROCKOUTS on another forum a few months ago and decided then, that this could be a viable solution ( to correct a potential problem ) that I 'might' be having.

It never got better or worse... so I bought the $15 rockouts and hung them on the bench in the garage for a rainy/snowy day.

I picked up some adjustable pushrods and yesterday decided to tear into it... GLAD I DID!

Once I got in there ( following the manual ) and took the rocker support housing off the rear cylinder, it was obvious that 'something' just wasn't right.

First clue was the right side bolt on the exhaust side.. VERY HARD to get out compared to the other 3

Second clue was the offset position of the rocker shaft itself...

Third clue was noticed looking into the bolt hole of the rocker support....