120ST woes.... it's going in for teardown...

- Thread starter Spazz

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Yessir... reference number already sentIs that going to be covered under warrantee ?

Sent from Note4 via TapaTalk

Damn! You wonder if all 120st's are like that.

Sent from my iPhone using Tapatalk

I doubt that, Bryan......I still need to find out exactly what has happened....

Damn! You wonder if all 120st's are like that.

Good question.

The 120 has a 7.575" connecting rod length and 4.625" stroke; Rod/Stroke= 1.637

Most common is a 7.667 connecting rod length and a 4.375 stroke; Rod/Stroke=1.752

A value of 1.75 is considered ideal by many respected engine builders.

The short ratio (1.637) makes the engine push the pistons hard against the cylinder walls causing the wear when combined with the higher piston velocities of the longer stroke.

My 120ST with 6500 miles is developing piston slap at start-up indicating significant piston and bore wear. So......what to do?

We only need to change 2 parts to fix a basically great motor.

1. Put in a 4.375 crank set. I would use the new S&S crank with SE pistons and stay with the SE lefty bearing in the bike.

2. Bore the cylinders .010 over to fit SE pistons 22575-07B. 10.5:1 compression with no other changes.

Now you have a 113" motor you can run as hard as you want for a long long time.

Optional:

1. Put in S&S premium lifters

Do not bore up to 4.125" making a 117. The pistons have less stability with shorter skirts and the cylinders are thin and will distort more.

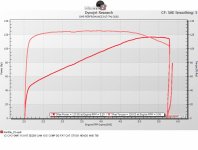

Proof: Here's a 113 built by GMR with the stock 120ST 259E cam and a D&D Fat Cat exhaust. Stock CVO heads and throttle body.

I think I'm heading in this direction.

Good info here: http://victorylibrary.com/mopar/rod-tech-c.htm

She is still under inspection... jugs have to be spec'd out... cams and bottom end are next...

Prepare yourself....

Now.. if the jugs are bad and out of spec.. this means new pistons.

This is where I got the itch...lol

Gonna bump up the compression a bit to work well with the TW9B-6 cams from Woods. I will also get tapered adjustable pushrods to make sure I have good clearance with the .630 lift of the cams...

May as well do a little upgrading ....since we are in it...hehehe

Sent from Note4 via TapaTalk

Prepare yourself....

Now.. if the jugs are bad and out of spec.. this means new pistons.

This is where I got the itch...lol

Gonna bump up the compression a bit to work well with the TW9B-6 cams from Woods. I will also get tapered adjustable pushrods to make sure I have good clearance with the .630 lift of the cams...

May as well do a little upgrading ....since we are in it...hehehe

Sent from Note4 via TapaTalk

B

Bones

Guest

I have watched you go through an amazing learning curve over the last year with your Street Glide, engine and sound. And, now with the Road Glide 120ST you are on another learning curve.....I'm guessing it's the most extensive lesson yet. I am sitting back watching and enjoying your determination to make your bike what you want. There are a hand full of guys on this site that show no fear when it comes to upgrading your bikes. I compliment and applaude everyones progress and success. I only wish I could see each bike in person to enjoy what y'all have done. Keep it comin'.

Thanks Bones.... as I said before... this is a hard pill to swallow, but if I can shed some insight to others that may need it in some way, shape or form... it's worth it to me. I have many guys that have contacted me over the last week with a wealth of info and in depth details. The also applauded me for 'coming out' with my issues as it helps people learn.I have watched you go through an amazing learning curve over the last year with your Street Glide, engine and sound. And, now with the Road Glide 120ST you are on another learning curve.....I'm guessing it's the most extensive lesson yet. I am sitting back watching and enjoying your determination to make your bike what you want. There are a hand full of guys on this site that show no fear when it comes to upgrading your bikes. I compliment and applaude everyones progress and success. I only wish I could see each bike in person to enjoy what y'all have done. Keep it comin'.

Sent from Note4 via TapaTalk

Will you be achieving the bump in compression with head work or dome pistons? I like the fact that you're going to get a little more out of it while it's apart. That makes plenty of sense to me. From what I've read in your other threads/posts, you already have an exhaust system that allows room for growth. Whichever way you decide to go, I'm sure you'll have a huge smile on your face the next time you press the starter button.

I'm sure you'll have a huge smile on your face the next time you press the starter button.

Big HP numbers are tempting.

What I'm afraid of is the huge big frown on your face the next time you need another rebuild.

I'm going in another direction with emphasis on usable power and long engine life. I want to ride my bike a lot of worry free miles.

Big HP numbers are tempting.

What I'm afraid of is the huge big frown on your face the next time you need another rebuild.

I'm going in another direction with emphasis on usable power and long engine life. I want to ride my bike a lot of worry free miles.

I hear ya Hulkss.... but at the rate I'm going.. it won't be long until I have another new sled in the garage.. LMAO!!! I have had a 2013 for 8 months... 2014 for 23 months and now my 2015.... NOT A GOOD TRACK RECORD!!!!

Seriously though... while I'm in it... I may as well do 'something' to ease my need for speed and power... sure the 120 was a nice jump in torque and power over the 103... but I just can't seem to be 'satisfied'... I WANT MORE!!!! I completely understand the longevity rationale... makes sense and I agree with you... just can't help myself thinking later, " Why didn't I do this or that?"

Yes, big power is big fun, but, you do have to pay a price.

I expect that a tear down inspection and overhaul will be needed every year during the off season (assuming you are putting that power to good use). I checked the service numbers in the manual for piston-to-bore clearance. It's .003" on the 103 and .006" on the 120R and 120ST. That's .001 of wear on the 103 and .003 of wear on the 120. Triple the wear allowance from as-built clearance in half the warranty time.

Not to mention the issues being experienced with the valve train and flywheel-rod assembly................

I expect that a tear down inspection and overhaul will be needed every year during the off season (assuming you are putting that power to good use). I checked the service numbers in the manual for piston-to-bore clearance. It's .003" on the 103 and .006" on the 120R and 120ST. That's .001 of wear on the 103 and .003 of wear on the 120. Triple the wear allowance from as-built clearance in half the warranty time.

Not to mention the issues being experienced with the valve train and flywheel-rod assembly................

I hear that Spazz lol. Just can't leave them alone got tweak this or that.

Just wait til we meet up again Jay.... LOL!!! I'm sure it will be much fun... AS USUAL!!! Tearin it up!!!! You got me off the line last time... and the time before that.... hmmmm..... but I did catch you! LMAO!!!

Much love Brother....miss ya!