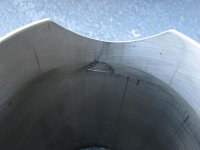

I started the rebuild of my 120ST. I want to to make it super reliable for a ride to Alaska this summer. Something about it did not sound right to me. Kind of like piston slap.

I'm going to completely disassemble it and rebuild. I'll keep posting as I go along. I only work on it a few evenings a week. I'll explain anything that is not clear in the factory service manual. Here goes......

First, off with the bags & side covers, seat, gas tank, and exhaust. The hardest part was getting the mufflers off. Slip-on maybe but not slip-off. I'll use a little high temp nickle anti-seize at the slip joint when they go back on.

Next off with the air cleaner, rocker boxes, and throttle body.

Take the throttle body off last, it's easier then to get a wrench on the bolts. The factory special intake manifold wrench p/n 94063-09 sux. Use a ground off hex wrench and a cheater bar. The lower rocker box wrench is good, p/n 94074-09. I did not need the H-D rocker cover bolt wrench p/n 94057-09 because I have custom 12 point fasteners on the covers. You don't need the special wrenches if you take the engine out of the frame first. I'll take it out in pieces and put it back without the cylinders & heads.

I'm going to completely disassemble it and rebuild. I'll keep posting as I go along. I only work on it a few evenings a week. I'll explain anything that is not clear in the factory service manual. Here goes......

First, off with the bags & side covers, seat, gas tank, and exhaust. The hardest part was getting the mufflers off. Slip-on maybe but not slip-off. I'll use a little high temp nickle anti-seize at the slip joint when they go back on.

Next off with the air cleaner, rocker boxes, and throttle body.

Take the throttle body off last, it's easier then to get a wrench on the bolts. The factory special intake manifold wrench p/n 94063-09 sux. Use a ground off hex wrench and a cheater bar. The lower rocker box wrench is good, p/n 94074-09. I did not need the H-D rocker cover bolt wrench p/n 94057-09 because I have custom 12 point fasteners on the covers. You don't need the special wrenches if you take the engine out of the frame first. I'll take it out in pieces and put it back without the cylinders & heads.