120 to 114 to 113 Twin Cam Engine Rebuild

- Thread starter hulkss

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

cool glad to hear she is running. I just got the call from Kendall Johnson Customs that my Short Block is ready.I had them do the Timken upgrade, bored the cases and install a S&S 4 5/8 crank. Its been killing me to see all the bikes on the road and mine is tore down.

Here's a photo of my Mighty-Might cooling fans. They come wired to work off an H-D accessory switch kit you mount in the fairing (not included: p/n 71400106 if you have the auxiliary lamp switch; p/n 71400105 if you don't). They seem to work fine and blow a surprising amount of air. I switch 'em on at long stop lights or in stop & go conditions. I painted over the Love Jugs logo on the mount.

I changed out my break-in oil to Liqui-Moly 10W-60 Synthetic. I like the wide viscosity range for an air cooled engine that can run hot or cold depending on the weather. No need for an oil discussion.

This Form-A-Funnel works great. Takes a little effort to stuff in place before you spin off the filter, but, no oil mess to clean up.

I changed out my break-in oil to Liqui-Moly 10W-60 Synthetic. I like the wide viscosity range for an air cooled engine that can run hot or cold depending on the weather. No need for an oil discussion.

This Form-A-Funnel works great. Takes a little effort to stuff in place before you spin off the filter, but, no oil mess to clean up.

The engine break-in is now complete with just over 200 miles and no more issues...whew. The bike pulls to red-line (110 mph) very smoothly and quickly in fourth gear with no noticeable drop in torque. Engine vibration is less than stock.

So it was time for the final step to confirm the build quality: a Cranking Compression Pressure test commonly called CCP.

I used this kit from Sears:

1. Ride bike until fully warmed up

2. Pull both spark plugs

3. Removed air filter and hold the throttle plate open with a screwdriver handle (too big to get sucked in)

4. Attach a remote starter switch (this avoids activating fuel injection, throttle, spark, and compression releases)

5. Attach CCP gauge to front cylinder

6. Ignition off, stop/run switch off

7. Crank to stable pressure on gauge (a few seconds) using remote starter switch

8. Repeat on rear cylinder

Pressures should be within 10% of each other. I measured 215 PSI front and 215 PSI rear. These are excellent numbers that indicate good ring and valve sealing. I am having no trouble at all with 91 octane fuel (no ping or spark knock).

So it was time for the final step to confirm the build quality: a Cranking Compression Pressure test commonly called CCP.

I used this kit from Sears:

1. Ride bike until fully warmed up

2. Pull both spark plugs

3. Removed air filter and hold the throttle plate open with a screwdriver handle (too big to get sucked in)

4. Attach a remote starter switch (this avoids activating fuel injection, throttle, spark, and compression releases)

5. Attach CCP gauge to front cylinder

6. Ignition off, stop/run switch off

7. Crank to stable pressure on gauge (a few seconds) using remote starter switch

8. Repeat on rear cylinder

Pressures should be within 10% of each other. I measured 215 PSI front and 215 PSI rear. These are excellent numbers that indicate good ring and valve sealing. I am having no trouble at all with 91 octane fuel (no ping or spark knock).

Now that the mechanical stuff is mostly over, it's time to turn attention to the Engine Control Module (ECM) and tuning. The Power Vision Target Tune file I mentioned in a previous post is installed with the fuel and spark tables I posted. It seems to run fine but it's time to do some data logging followed by tuning. Then we will see measurements of what is really going on in the engine.

Here is a table listing the signals available from the Power Vision tuner and those I selected to log on my next ride. I selected 32 data channels which is the maximum.

View attachment Log Signals.pdf

Here is a table listing the signals available from the Power Vision tuner and those I selected to log on my next ride. I selected 32 data channels which is the maximum.

View attachment Log Signals.pdf

I went for a short ride logging data and I saved the file. The Power Vision can record a massive amount of data. For me it was recording about 10 data sets per second (32 signals in each set). A data file of nearly 16000 rows in 32 columns from a 24 minute ride. Looking at the data, I did not see any spark knock events from the Delphi Ion-Sense Ignition System so that was good.

I used a program called Mega Log Viewer HD to look at the data. Here is a histogram (RPM vs MAP) that shows the difference in fuel/air lambda as measured in the exhaust (Wide Band O2 sensors) from what was commanded by the ECM. These small differences mean the Volumetric Efficiency (VE) tables are quite good and the system is working well.

Here's how engine fueling looks plotted with fuel injector pulse width on the vertical axis and (manifold absolute pressure) X (volumetric efficiency) on the horizontal axis. The color represents Lambda. You can see how the fueling increases and the mixture gets richer with increased cylinder air intake. I'm not sure why the rear cylinder has a different shape to the data cloud. Maybe it will change with some road tuning.

Here's how the ignition timing looks plotted with rpm on the vertical axis and (manifold absolute pressure) X (volumetric efficiency) on the horizontal axis. The color represents Spark Advance. You can see how the timing retards with increased cylinder air intake and advances with rpm.

I used a program called Mega Log Viewer HD to look at the data. Here is a histogram (RPM vs MAP) that shows the difference in fuel/air lambda as measured in the exhaust (Wide Band O2 sensors) from what was commanded by the ECM. These small differences mean the Volumetric Efficiency (VE) tables are quite good and the system is working well.

Here's how engine fueling looks plotted with fuel injector pulse width on the vertical axis and (manifold absolute pressure) X (volumetric efficiency) on the horizontal axis. The color represents Lambda. You can see how the fueling increases and the mixture gets richer with increased cylinder air intake. I'm not sure why the rear cylinder has a different shape to the data cloud. Maybe it will change with some road tuning.

Here's how the ignition timing looks plotted with rpm on the vertical axis and (manifold absolute pressure) X (volumetric efficiency) on the horizontal axis. The color represents Spark Advance. You can see how the timing retards with increased cylinder air intake and advances with rpm.

I just got back from a 9400 mile ride to Alaska for 10,400 miles total on the engine. It ran great the whole time. Stopped for an engine oil change at 4000 miles. Not a single problem with anything on the entire bike. Amazing. The Alcan Highway gave it a good beating.

I ran it very hard at times. My fuel mileage per fill-up ranged from a low of 27 mpg to a high of 46 mpg. Average was 38 mpg with 247 gallons of fuel consumed. Oil consumption was only about 8 ounces per 5000 miles.

I'll probably open the top end and cam chest again this winter just for fun and to see what is going on inside.

I ran it very hard at times. My fuel mileage per fill-up ranged from a low of 27 mpg to a high of 46 mpg. Average was 38 mpg with 247 gallons of fuel consumed. Oil consumption was only about 8 ounces per 5000 miles.

I'll probably open the top end and cam chest again this winter just for fun and to see what is going on inside.

I just got back from a 9400 mile ride to Alaska for 10,400 miles total on the engine. It ran great the whole time. Stopped for an engine oil change at 4000 miles. Not a single problem with anything on the entire bike. Amazing. The Alcan Highway gave it a good beating.

I ran it very hard at times. My fuel mileage per fill-up ranged from a low of 27 mpg to a high of 46 mpg. Average was 38 mpg with 247 gallons of fuel consumed. Oil consumption was only about 8 ounces per 5000 miles.

I'll probably open the top end and cam chest again this winter just for fun and to see what is going on inside.

That's what I'm talking about!

That's what I'm talking about!

great to hear you're back safe and that all went well.

Sent from my iPhone using Tapatalk

great to hear you're back safe and that all went well.

All did go well, however, I just gave the engine a critical listen and it is again making sounds I don't like.

I'll open the top end and cam chest after labor day for a health check.

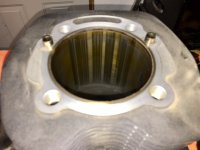

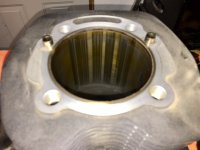

I have the cam chest disassembled and the complete top end off the engine to investigate my engine noises. Everything looks really good except one of the cylinder bores. Check out this weird wear pattern on the side of the bore, only on this one side. Normally the front or back piston thrust face wears on the bore.  Something is out of spec here I would think.

Something is out of spec here I would think.

Update from http://www.mmec.net/diagnostic.htm

This piston has many vertical seizure marks around the circumference. This cylinder was bored to a diameter that was too small for

the piston. As the piston started its thermal expansion, the piston pressed up against the cylinder walls and started to seize. I either got that piston too hot and it nearly seized in the bore or the bore was under size.

I'm putting in new flat top 113 CVO Mahle pistons from Suburban Speed with new H-D SE 4.06 bore cylinders. Check out the difference as compared the H-D pistons which I'm told are from Wiseco. Much more skirt area and a lower expansion forged alloy for a close quiet fit in the cylinder.

The flat-top Mahle pistons will lower the cylinder compression ratio to 10:1 (93cc heads) to work with new SE-585 cams. This is a midrange torque cam which should out perform my current SE-259E cams up to about 4500 RPM. These are only available in chain drive so I am putting in the SE billet cam plate and high flow oil pump. This is designed to work with the hydraulic chain tensioners. I'm also putting in new SE hydraulic tappets as it sure sounded like I had some valve lifter noise. These should be fine with the beehive valve springs I am using.

Update from http://www.mmec.net/diagnostic.htm

This piston has many vertical seizure marks around the circumference. This cylinder was bored to a diameter that was too small for

the piston. As the piston started its thermal expansion, the piston pressed up against the cylinder walls and started to seize. I either got that piston too hot and it nearly seized in the bore or the bore was under size.

I'm putting in new flat top 113 CVO Mahle pistons from Suburban Speed with new H-D SE 4.06 bore cylinders. Check out the difference as compared the H-D pistons which I'm told are from Wiseco. Much more skirt area and a lower expansion forged alloy for a close quiet fit in the cylinder.

The flat-top Mahle pistons will lower the cylinder compression ratio to 10:1 (93cc heads) to work with new SE-585 cams. This is a midrange torque cam which should out perform my current SE-259E cams up to about 4500 RPM. These are only available in chain drive so I am putting in the SE billet cam plate and high flow oil pump. This is designed to work with the hydraulic chain tensioners. I'm also putting in new SE hydraulic tappets as it sure sounded like I had some valve lifter noise. These should be fine with the beehive valve springs I am using.

My engine began to clatter a bit like piston slap or a flat lifter when cold started after about 5000 miles. This was also after some long stretches of wide-open throttle.

I now believe my oil pressure may have been too low resulting too little flow through the piston cooling jets. I set my new S&S oil pressure regulator to 30 psi at warm (not fully hot) idle. The S&S regulator is very effective and oil pressure was 32 psi at speed. This is plenty of pressure thinking only about lubrication and hydraulic tappets.

The H-D oil pressure regulators when coupled with their high flow pumps provide more like 45-50 psi at higher rpm. This will spray much more oil from the piston cooling jets which is probably very important for a high power engine operated at full throttle.

Here's an interesting article that shows the effect of oil pressure, oil jet flow, and piston temperature when using cooling jets.

Piston Cooling Oil Jets

I'm going to put in new piston cooling jets before I reassemble the engine just in case they may be partially plugged up.

I now believe my oil pressure may have been too low resulting too little flow through the piston cooling jets. I set my new S&S oil pressure regulator to 30 psi at warm (not fully hot) idle. The S&S regulator is very effective and oil pressure was 32 psi at speed. This is plenty of pressure thinking only about lubrication and hydraulic tappets.

The H-D oil pressure regulators when coupled with their high flow pumps provide more like 45-50 psi at higher rpm. This will spray much more oil from the piston cooling jets which is probably very important for a high power engine operated at full throttle.

Here's an interesting article that shows the effect of oil pressure, oil jet flow, and piston temperature when using cooling jets.

Piston Cooling Oil Jets

I'm going to put in new piston cooling jets before I reassemble the engine just in case they may be partially plugged up.

Because of the weird bore scuffing on one side of one cylinder, I wanted to check if the wrist pin is parallel to the cylinder mounting face on the case. If not, the piston would be cocked in the bore. I put in a wrist pin and it rested perfectly square on a pair of gage bars.

Here's a picture of a piston cooling jet. I sure don't want to drop one of those jets or screws or anything else into the engine cases when I change them.

Here's a picture of a piston cooling jet. I sure don't want to drop one of those jets or screws or anything else into the engine cases when I change them.

I will be keeping an eye out for updates to see how things are going...

Thanks for the tips you have provided.

I did figure out why it was a PITA to adjust my adjustable pushrods. I was supposed to use special pushrod cover tubes that telescope more to expose the adjusting nuts.

Like these Colony 2148-8: